| 合金名称 | 成分 | 特点 | 使用案例 |

|---|---|---|---|

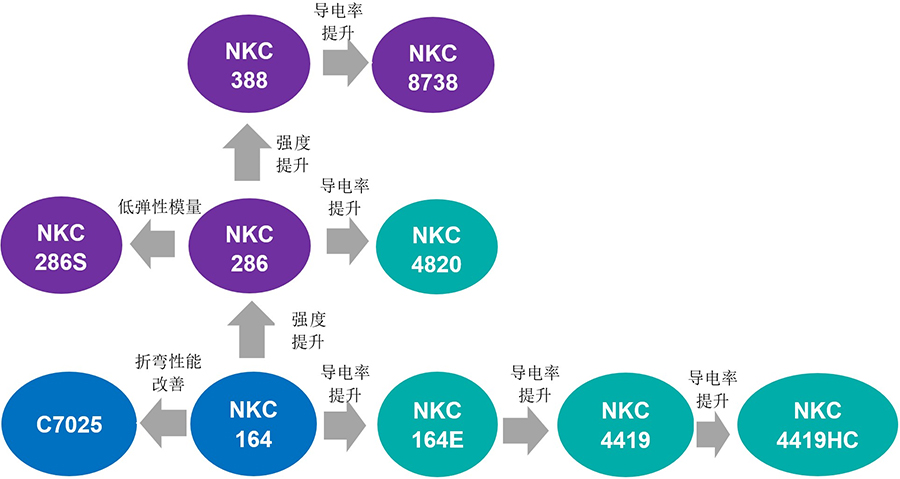

| Cu-3.0Ni-0.65Si-0.15Mg | 代表性可鲁逊合金 | 连接器、引线框架、CPU插槽 | |

| Cu-1.6Ni-0.4Si-0.5Sn-0.4Zn | 强度和导电率平衡性优异的可鲁逊合金 | 线束、连接器 | |

| Cu-2.8Ni-0.6Si-0.5Sn-0.4Zn | 强度高于C7025的可鲁逊合金 | 连接器、线束 | |

| Cu-2.8Ni-0.6Si-0.5Sn-0.4Zn | NKC286的低纵向弹性化 | 连接器、线束 | |

| Cu-3.8Ni-0.8Si-0.1Mg-0.13Mn | 可鲁逊合金中最高等级的强度 | 连接器、开关 | |

| Cu-1.6Ni-0.35Si | 具备弹性的高导电可鲁逊合金 | 连接器、电池端子 | |

| Cu-1.9Co-0.44Si | 具备弹性的高导电可鲁逊合金 | 连接器、电池端子 | |

| Cu-1.6Co-0.5Ni-0.48Si | 具备弹性的高强度、高导电可鲁逊合金 | 连接器、电池端子 |

化学成分 Chemical Composition(wt%)

| 产品名称 Copper Alloy Name | C7025 | NKC164 | NKC286 | NKC286S | NKC388 | NKC164E | NKC4419 | NKC4419HC | NKC4820 | NKC8738 |

|---|---|---|---|---|---|---|---|---|---|---|

| 化学成分 Chemical Composition(wt%) | Cu : Rest Ni : 3.0 Si : 0.65 Mg : 0.15 | Cu : Rest Ni : 1.6 Si : 0.4 Sn : 0.5 Zn : 0.4 | Cu : Rest Ni : 2.8 Si : 0.6 Sn : 0.5 Zn : 0.4 | Cu : Rest Ni : 2.8 Si : 0.6 Sn : 0.5 Zn : 0.4 | Cu : Rest Ni : 3.8 Si : 0.8 Mg : 0.1 Mn : 0.13 | Cu : Rest Ni : 1.6 Si : 0.35 | Cu : Rest Co : 1.9 Si : 0.44 | Cu : Rest Co : 1.9 Si : 0.44 | Cu : Rest Co : 1.6 Ni : 0.5 Si : 0.48 | Cu : Rest Ni : 3.55 Si : 0.87 Co: 0.25 |

物理特性 Physical Properties

| 产品名称 Copper Alloy Name | C7025 | NKC164 | NKC286 | NKC286S | NKC388 | NKC164E | NKC4419 | NKC4419HC | NKC4820 | NKC8738 |

|---|---|---|---|---|---|---|---|---|---|---|

| 比重 (g/cm3) Specific Gravity | 8.82 | 8.87 | 8.87 | 8.87 | 8.82 | 8.89 | 8.85 | 8.85 | 8.86 | 8.83 |

| 纵向弹性模量 (GPa) Modulus of Elasticity | 131 SH:120 | 127 | 127 | 110 | SH,ESH:123 XSH:123,TD:135 USH: 120, TD:140 | 120 | 127 | 127 | 120 | 131 |

| 导电率 (%IACS)(@20℃) Electrical Conductivity | 45 SH:48 TM04S:50 | 43 | 41 | 41 | SH: 38 ESH, XSH: 34 USH: 32 | 55 | 65 | 72 | 60 | 42 |

| 体积电阻率(nΩ・m)(@20℃) Specific Resistance | 38 SH:35 TM04S:34 | 40 | 42 | 42 | SH: 45 ESH, XSH: 51 USH: 54 | 30 | 27 | 24 | 29 | 41 |

| 导热率(W/(m・K)) Thermal Conductivity | 180 SH:191 TM04S:200 | 170 | 165 | 165 | SH: 160 ESH, XSH:143 USH: 136 | 240 | 260 | 291 | 245 | 172 |

| 线性膨胀系数 (×10-6 /K)(@20~300℃) Thermal Expansion Coefficient | 17.6 | 17.6 | 17.4 | 17.4 | 17.6 | 17.7 | 17.8 | 17.8 | 17.6 | 17.6 |

| 泊松比 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 |

机械特性 Mechanical Properties

| 产品名称 Copper Alloy Name | C7025 | NKC164 | NKC286 | NKC286S | NKC388 | NKC164E | NKC4419 | NKC4419HC | NKC4820 | NKC8738 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 抗拉强度(MPa) Tensile Strength USH | 1/4H | TR02:607-726(650) | - | - | - | - | - | 520-650(600) | - | - | - |

| 1/2H | SH:800-950(860) | 560-680(640) | 710-840(780) | 730-870(800) | - | - | - | - | - | - | |

| H | TM02: 650-740(725) | 620-740(680) | 760-890(830) | 800-940(880) | - | 590-680(630) | 590-720(670) | (600) | - | - | |

| EH | TM03: 680-760(744) | 680-800(730) | 810-940(880) | - | - | 620-760(690) | - | - | (740) | - | |

| SH | TM04: 750-840(814) | - | - | - | 890-990(940) | - | - | - | - | - | |

| ESH | TM04S: 710-830(800) | - | - | - | 930-1030(980) | - | - | - | - | (1010) | |

| XSH | - | - | - | - | 970-1090(1030) | - | - | - | - | - | |

| USH | - | - | - | - | 970-1090(1030 ), TD: 1070-1190(1130) | - | - | - | - | - | |

| GSH | - | - | - | - | - | - | - | - | - | - | |

| ESH(HB) | - | - | - | - | - | - | - | - | - | - | |

| XSH(HB) | - | - | - | - | - | - | - | - | - | - | |

| 0.2%屈服强度(MPa) 0.2% Yield Strength | 1/4H | TR02: 550min(575) | - | - | - | - | - | 370-500(480) | - | - | - |

| 1/2H | SH: - | 520-670(610) | 690-830(760) | 695-835(765) | - | - | - | - | - | - | |

| H | TM02: 585min(644) | 580-730(660) | 740-880(810) | 775-915(845) | - | 540-680(610) | 570-700(650) | (590) | - | - | |

| EH | TM03: 655min(710) | 640-790(720) | 790-930(860) | - | - | 600-740(670) | - | - | (710) | - | |

| SH | TM04: 740min(800) | - | - | - | 860-960(910) | - | - | - | - | - | |

| ESH | TM04S: 700min(780) | - | - | - | 900-1000(950) | - | - | - | - | (970) | |

| XSH | - | - | - | - | 940-1060(1000) | - | - | - | - | - | |

| USH | - | - | - | - | 940-1060(1000) TD:1040-1160(1100) | - | - | - | - | - | |

| GSH | - | - | - | - | - | - | - | - | - | - | |

| ESH(HB) | - | - | - | - | - | - | - | - | - | - | |

| XSH(HB) | - | - | - | - | - | - | - | - | - | - | |

| 延伸率(%) Elongation | 1/4H | TR02: 6.0min(10.0) | - | - | - | - | - | 10min(17) | - | - | - |

| 1/2H | SH: 1.0min(3) | 5min(8.0) | 3min(6.0) | 3min(7.0) | - | - | - | - | - | - | |

| H | TM02: 10.0min(13.0) | 3min(6.0) | 2min(4.0) | 1min(2.0) | - | 5min(12) | 2min(8) | (8) | - | - | |

| EH | TM03: 5.0min(9.0) | 1min(4.0) | 1min(2.0) | - | - | 2min(5) | - | - | (3) | - | |

| SH | TM04: 1.0min(3.0) | - | - | - | 1.0min(3.0) | - | - | - | - | - | |

| ESH | TM04S: 1.0min(4) | - | - | - | 1.0min(2.5) | - | - | - | - | (3) | |

| XSH | - | - | - | - | 1.0min(2.0) | - | - | - | - | - | |

| USH | - | - | - | - | 1.0min(2.0) | - | - | - | - | - | |

| GSH | - | - | - | - | - | - | - | - | - | ||

| ESH(HB) | - | - | - | - | - | - | - | - | - | - | |

| XSH(HB) | - | - | - | - | - | - | - | - | - | - | |

硬度(Hv)Vickers Hardness | 1/4H | TR02: 180-220(204) | - | - | - | - | - | 160-210(180) | - | - | - |

| 1/2H | SH: 235-300(255) | 160-230(190) | 200-270(230) | 215-285(250) | - | - | - | - | - | - | |

| H | TM02: 190-240(215) | 170-240(200) | 210-280(245) | 250-320(285) | - | 160-220(200) | 180-220(200) | (190) | - | - | |

| EH | TM03: 200-250(235) | 200-270(220) | 230-300(260) | - | - | 170-230(210) | - | - | (230) | - | |

| SH | TM04:225-275(248) | - | - | - | 250-310(280) | - | - | - | - | - | |

| ESH | TM04S: 210-260(246) | - | - | - | 265-325(295) | - | - | - | - | (305) | |

| XSH | - | - | - | - | 285-350(325) | - | - | - | - | - | |

| USH | - | - | - | - | 285-350(325) | - | - | - | - | - | |

| GSH | - | - | - | - | - | - | - | - | - | - | |

| ESH(HB) | - | - | - | - | - | - | - | - | - | - | |

| XSH(HB) | - | - | - | - | - | - | - | - | - | - | |

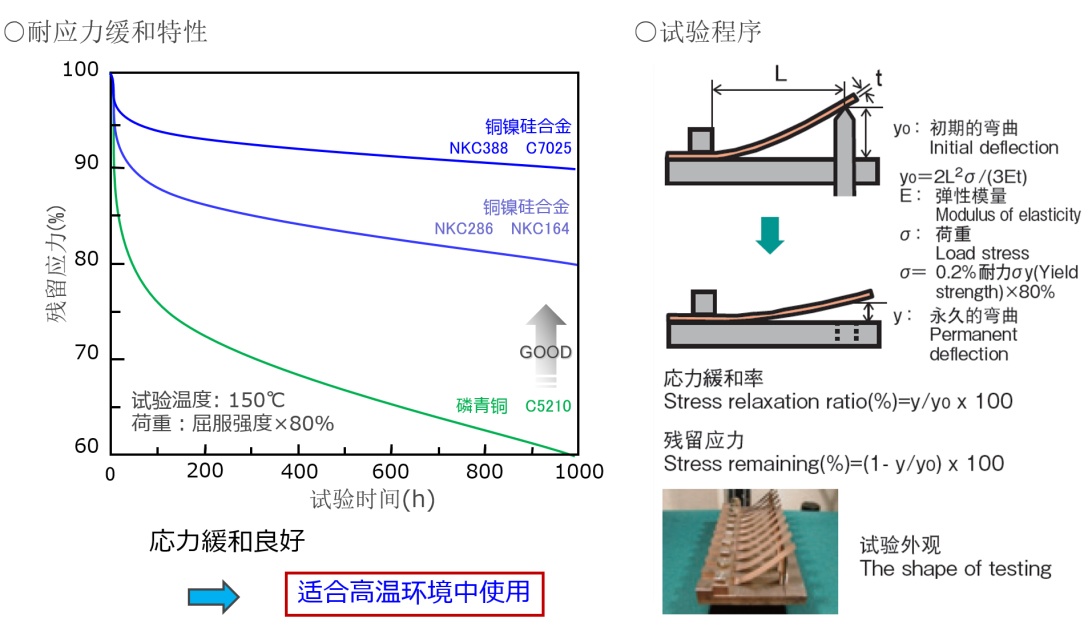

残留应力率(%) Remaining Stress @150℃, 1000h, 0.8σ Thickness Range: t≥0.08mm ※ 参考值 Reference data | 91 | 85 | 85 | 85 | 92 | 77 | 76 | - | 82 | - | |

折弯加工性 Bend Formability

| 产品名称 Copper Alloy Name | C7025 | NKC164 | NKC286 | NKC286S | NKC388 | NKC164E | NKC4419 | NKC4419HC | NKC4820 | NKC8738 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 安全折弯半径/板厚 Minimum Bend Radius / t (Badway) | 1/2H | TR02: 4.0 | 0.0 | 0.0 | 0.0 | - | - | 1/4H : 0.0 | - | - | - |

| H | TM02: 0.0 | 0.0 | 0.5 | 1.0 <t=0.08mm> | - | 0.0 | 0.7 | - | - | - | |

| EH | TM03: 1.0 | 1.5 | 1.7 | - | - | 0.2 | - | - | - | ||

| SH | TM04: 5.0 | - | - | - | 1.0 | - | - | - | - | ||

| ESH | TM04S: 1.0 <t=0.1mm> | - | - | - | 3.0 | - | - | - | - | ||

| XSH | - | - | - | - | - | - | - | - | - | - | |

| USH | - | - | - | - | - | - | - | - | - | - | |

| GSH | - | - | - | - | - | - | - | - | - | - | |

| ESH(HB) | - | - | - | - | - | - | - | - | - | - | |

| XSH(HB) | - | - | - | - | - | - | - | - | - | - | |

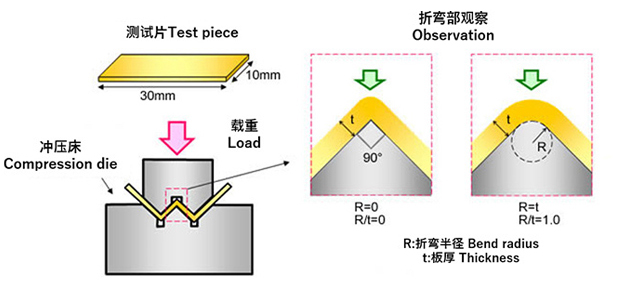

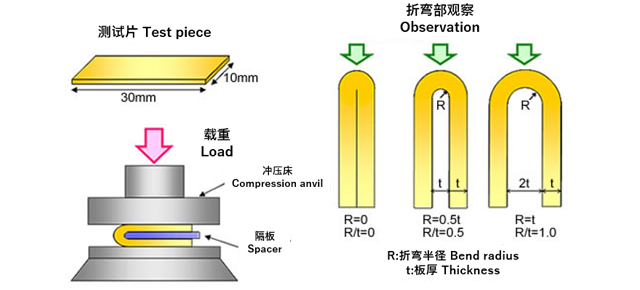

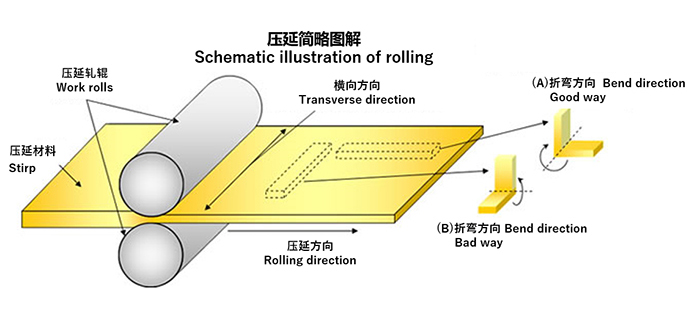

术语说明 Explanation of technical terms

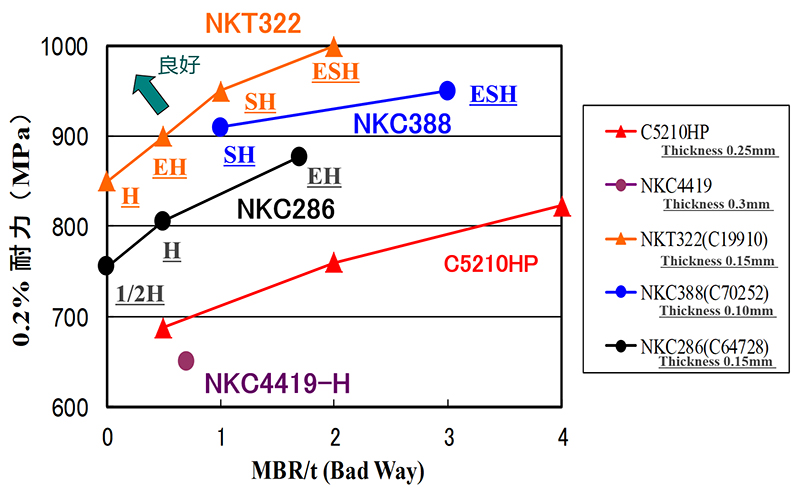

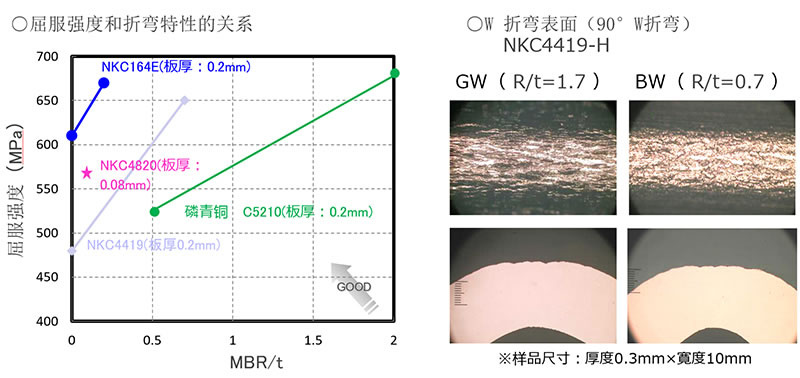

将不会出现裂纹的折弯半径R除以材料板厚t所得的值定义为安全折弯半径(MBR/t)。可以说MBR/t的数值越小,材料的折弯加工性越好。

将不会出现裂纹的折弯半径R除以材料板厚t所得的值定义为安全折弯半径(MBR/t)。可以说MBR/t的数值越小,材料的折弯加工性越好。 将没有发生开裂的折弯半径R除以材料板厚t所得的值定义为安全折弯半径(MBR/t)。可以说MBR/t的数值越小,材料的折弯加工性越好。

将没有发生开裂的折弯半径R除以材料板厚t所得的值定义为安全折弯半径(MBR/t)。可以说MBR/t的数值越小,材料的折弯加工性越好。 铜合金的折弯加工性取决于材料的压延方向。折弯直线与压延方向正交时为Good Way,平行时为Bad Way。

铜合金的折弯加工性取决于材料的压延方向。折弯直线与压延方向正交时为Good Way,平行时为Bad Way。折弯加工性