化学成分(wt%) Chemical Composition

| 产品名称 Copper Alloy Name | 高性能磷青铜 Hyper Phosphor Bronze | 一般磷青铜 Phosphor Bronze | |

|---|---|---|---|

| C5210(HP) | C5240(HP) | C5191 | |

| 化学成分(wt%) Chemical Composition | Cu : Rest Sn : 8.0 P : 0.2 | Cu : Rest Sn : 10.0 P : 0.15 | Cu : Rest Sn : 6.0 P : 0.2 |

物理特性 Physical Properties

| 产品名称 Copper Alloy Name | 高性能磷青铜 Hyper Phosphor Bronze | 一般磷青铜 Phosphor Bronze | |

|---|---|---|---|

| C5210(HP) | C5240(HP) | C5191 | |

| 比重(g/cm3) Specific Gravity | 8.80 | 8.78 | 8.83 |

| 纵向弹性模量(GPa) Modulus of Elasticity | 110 | 100 | 110 |

| 导电率(%IACS @ 20℃) Electrical Conductivity | 12 | 10 | 14 |

| 体积抵抗率(nΩ·m)/(@20℃) Specific Resistance | 144 | 157 | 133 |

| 热传导率(W/(m·k) Thermal Conductivity | 63 | 50 | 57 |

| 线性膨胀系数(x10-6/K)(@20~300℃) Thermal Expansion Coefficient | 18.2 | 18.4 | 18.0 |

| 泊松比 Poisson's Ratio | 0.33 | 0.33 | 0.33 |

机械特性 Mechanical Properties

| 产品名称 Copper Alloy Name | 高性能磷青铜 Hyper Phosphor Bronze | 普通磷青铜 Phosphor Bronze | ||

|---|---|---|---|---|

| C5210(HP) | C5240(HP) | C5191 | ||

抗拉强度(MPa) Tensile Strength | 1/4H | - | - | 390-510 |

| 1/2H | - | - | 490-610 | |

| H | 590-705(636) | 650-750(708) | 590-685 | |

| EH | 685-785(729) | 750-850(805) | 635min | |

| SH | 735-835(790) | 850-950(866) | - | |

| ESH | 770-885(853) | 950-1050(998) | - | |

| XSH | 835-1000(918) | 1000-1200(1039) | - | |

0.2%屈服强度(MPa) 0.2% Yield Strength | 1/4H | - | - | - |

| 1/2H | - | - | - | |

| H | (565) | 580-690(617) | - | |

| EH | (688) | 650-790(755) | - | |

| SH | (760) | 780-920(813) | - | |

| ESH | (823) | 900-1030(935) | - | |

| XSH | (879) | 950-1190(997) | - | |

延伸率(%) Elongation | 1/4H | - | - | 35min |

| 1/2H | - | - | 20min | |

| H | 20min(33.4) | 11min(29.6) | 8min | |

| EH | 11min(22.1) | 9min(18.5) | 5min | |

| SH | 9min(17.8) | 5min(11.6) | - | |

| ESH | 5min(12.0) | 1min(2.8) | - | |

| XSH | 1min(2.8) | (1.1) | - | |

硬度(Hv) Vickers Hardness | 1/4H | - | - | 100-160 |

| 1/2H | - | - | 150-205 | |

| H | 185-235 | 200-240 | 180-230 | |

| EH | 210-260 | 230-270 | 200min | |

| SH | 230-270 | 250-290 | - | |

| ESH | 245-285 | 270-310 | - | |

| XSH | 270-350 | 290min | - | |

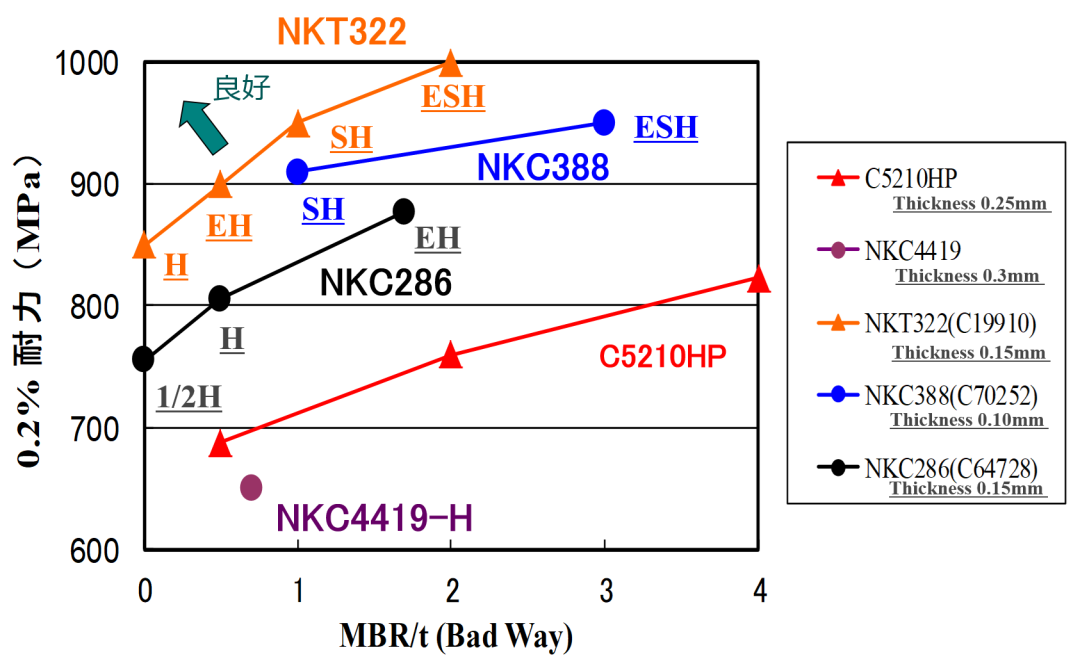

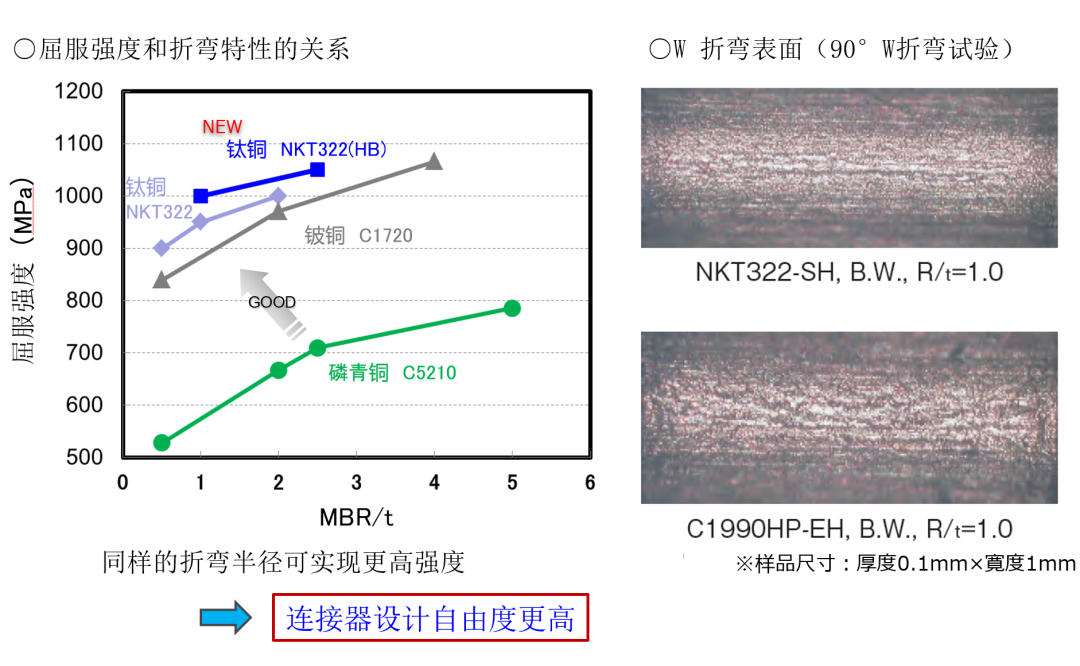

特性加工性 Bend Formability

| 产品名称 Copper Alloy Name | 高性能磷青铜 Hyper Phosphor Bronze | 普通磷青铜 Phosphor Bronze | ||

|---|---|---|---|---|

| C5210(HP) | C5240(HP) | C5191 | ||

| 安全折弯半径/板厚 Minimum Bend Radius / t Badway | 1/2H | - | - | - |

| H | 0.0 | 0.0 (t=0.1mm) | - | |

| EH | 0.5 | 1.0 (t=0.1mm) | - | |

| SH | 2.0 | 3.0 (t=0.1mm) | - | |

| ESH | 4.0 | - | - | |

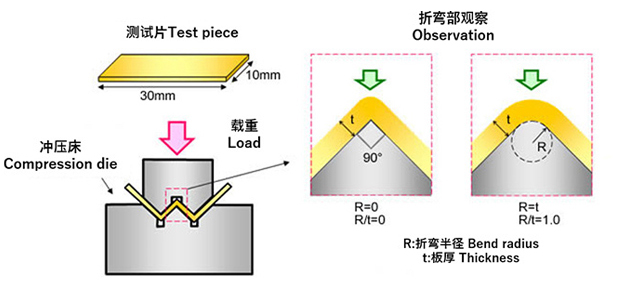

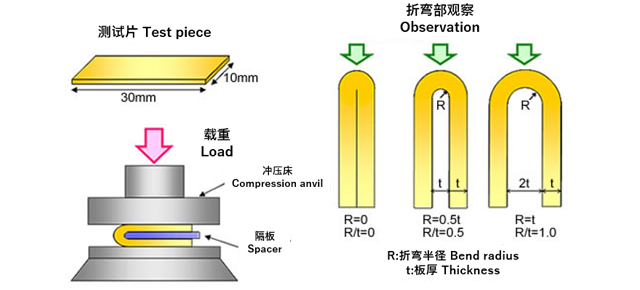

术语说明 Explanation of technical terms

将不会出现裂纹的折弯半径R除以材料板厚t所得的值定义为安全折弯半径(MBR/t)。可以说MBR/t的数值越小,材料的折弯加工性越好。

将不会出现裂纹的折弯半径R除以材料板厚t所得的值定义为安全折弯半径(MBR/t)。可以说MBR/t的数值越小,材料的折弯加工性越好。 将没有发生开裂的折弯半径R除以材料板厚t所得的值定义为安全折弯半径(MBR/t)。可以说MBR/t的数值越小,材料的折弯加工性越好。

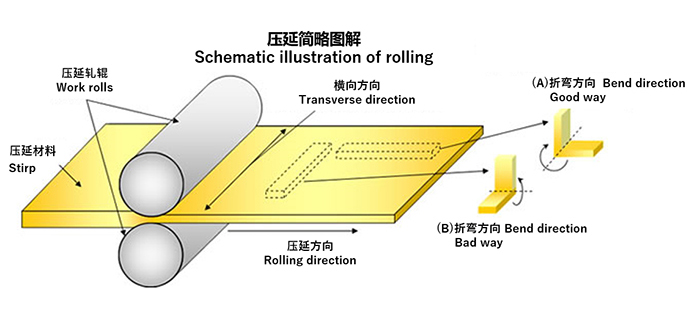

将没有发生开裂的折弯半径R除以材料板厚t所得的值定义为安全折弯半径(MBR/t)。可以说MBR/t的数值越小,材料的折弯加工性越好。 铜合金的折弯加工性取决于材料的压延方向。折弯直线与压延方向正交时为Good Way,平行时为Bad Way。

铜合金的折弯加工性取决于材料的压延方向。折弯直线与压延方向正交时为Good Way,平行时为Bad Way。