化学成分 Chemical Composition(wt%)

| 产品名称 Copper Alloy Name | 钛铜 TiCu | ||

|---|---|---|---|

| C1995HP | C1990HP | NKT322 | |

| 化学成分 Chemical Composition(wt%) | Cu : Bal. Ti : 4.0 | Cu : Bal. Ti : 3.0 | Cu : Bal. Ti : 3.0 Fe : 0.2 |

物理特性 Physical Properties

| 产品名称 Copper Alloy Name | 钛铜 TiCu | ||

|---|---|---|---|

| C1995HP | C1990HP | NKT322 | |

| 比重(g/cm3) Specific Gravity | 8.60 | 8.70 | 8.70 |

| 纵向弹性模量(GPa) Modulus of Elasticity | 134 | 127 XSH:115 | 120 |

| 导电率(%IACS@20℃) Electrical Conductivity | 8 | 12 | 12 |

体积电阻率(nΩ·m)/(@20℃) Specific Resistance | 216 | 144 | 144 |

| 热传导率(W/(m·k) Thermal Conductivity | 39 | 54 | 54 |

| 热膨胀系数(x10-6/K)(@20~300℃) Thermal Conductivity | 18.6 | 18.6 | 18.0 |

| 泊松比 Poisson's Ratio | 0.33 | 0.33 | 0.33 |

机械特性 Mechanical Properties

| 产品名称 Copper Alloy Name | 钛铜 TiCu | |||

|---|---|---|---|---|

| C1995HP | C1990HP | NKT322 | ||

| 抗拉强度(MPa) Tensile Strength | 1/4H | - | - | - |

| H | - | - | 900-1000(950) | |

| EH | - | 885-1080 | 920-1020(970) | |

| SH | - | 910-1110 | 970-1100(1020) | |

| ESH | - | 1000-1180 | 1010-1200(1070) | |

| ESH(HB) | - | - | 1010-1200(1070) | |

| XSH | - | 1050-1300(1150) | - | |

| XSH(HB) | - | - | 1050-1250(1120) | |

| GSH | (1540) | 1300-1600(1400) (板厚≦0.1mm) | - | |

| 0.2%屈服强度(MPa) 0.2% Yield Strength | 1/4H | - | - | - |

| H | - | - | 800-900(850) | |

| EH | - | 780-930 | 850-950(900) | |

| SH | - | 810-960 | 900-1000(950) | |

| ESH | - | 950-1100 | 950-1050(1000) | |

| ESH(HB) | - | - | 950-1050(1000) | |

| XSH | - | (1120) | - | |

| XSH(HB) | - | - | 1000-1150(1050) | |

| GSH | (1530) | (1390) | - | |

| 延伸率(%) Elongation | 1/4H | - | - | - |

| H | - | - | 12min(18.0) | |

| EH | - | 10min(17.0) | 10min(15.0) | |

| SH | - | 8min(14.0) | 6min(10.0) | |

| ESH | - | (3.0) | 3min(5.0) | |

| ESH(HB) | (0.5) | - | (7.0) | |

| XSH | - | - | - | |

| XSH(HB) | - | - | (5.0) | |

| GSH | - | - | - | |

| 硬度(Hv) Vickers Hardness | 1/4H | - | - | - |

| H | - | - | (300) | |

| EH | - | 280min(300) | (310) | |

| SH | - | 300min(320) | (320) | |

| ESH | - | 320min(340) | (340) | |

| ESH(HB) | - | - | (340) | |

| XSH | - | (340) | - | |

| XSH(HB) | - | - | (350) | |

| GSH | 460 | (400) | - | |

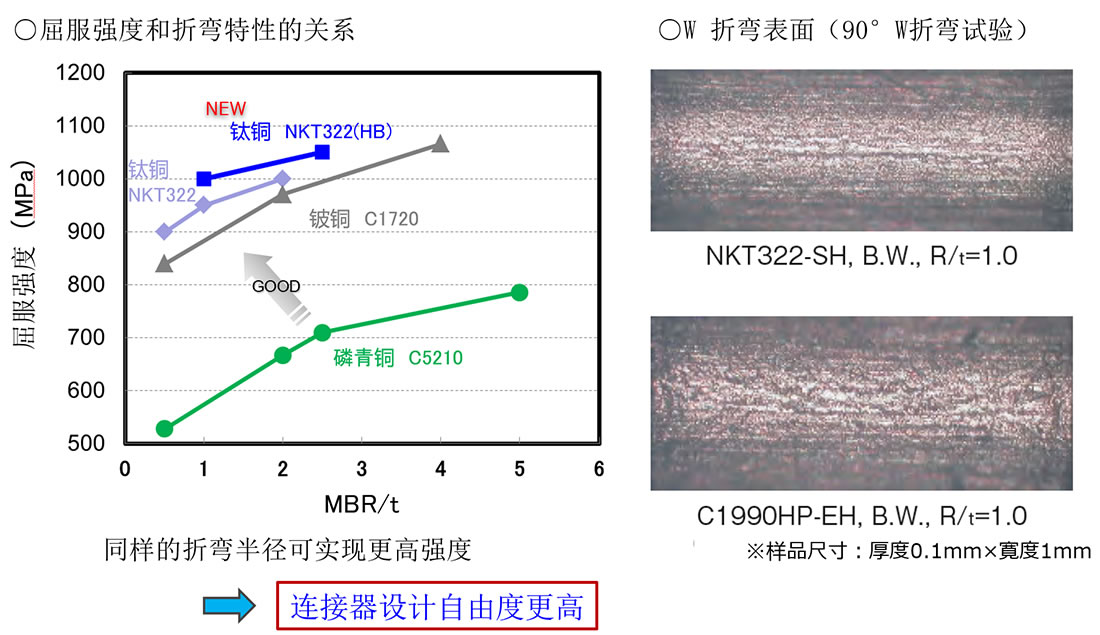

折弯加工性 Bend Formability

| 产品名称 Copper Alloy Name | 钛铜 TiCu | |||

|---|---|---|---|---|

| C1995 | C1990HP | NKT322 | ||

| 安全折弯半径/板厚 Minimum Bend Radius / t (Badway) | H | - | - | 0 |

| EH | - | 1.0 | 0.5 | |

| SH | - | 2.0 | 1.0 | |

| ESH | - | ≧5.0 | 2.0(t=0.1mm) | |

| ESH(HB) | - | - | 0(t=0.06mm) | |

| XSH(HB) | - | - | 2.0(t=0.06mm) | |

术语说明 Explanation of technical terms

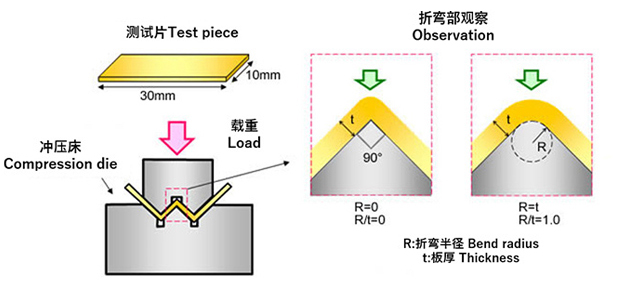

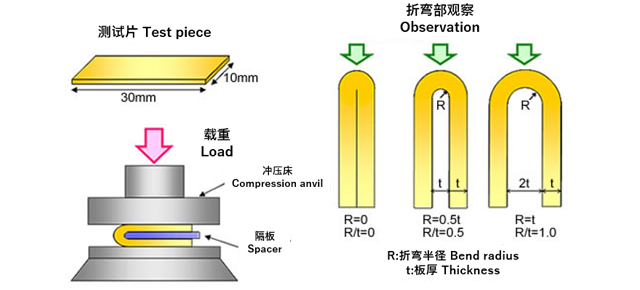

将不会出现裂纹的折弯半径R除以材料板厚t所得的值定义为安全折弯半径(MBR/t)。可以说MBR/t的数值越小,材料的折弯加工性越好。

将不会出现裂纹的折弯半径R除以材料板厚t所得的值定义为安全折弯半径(MBR/t)。可以说MBR/t的数值越小,材料的折弯加工性越好。 将没有发生开裂的折弯半径R除以材料板厚t所得的值定义为安全折弯半径(MBR/t)。可以说MBR/t的数值越小,材料的折弯加工性越好。

将没有发生开裂的折弯半径R除以材料板厚t所得的值定义为安全折弯半径(MBR/t)。可以说MBR/t的数值越小,材料的折弯加工性越好。 铜合金的折弯加工性取决于材料的压延方向。折弯直线与压延方向正交时为Good Way,平行时为Bad Way。

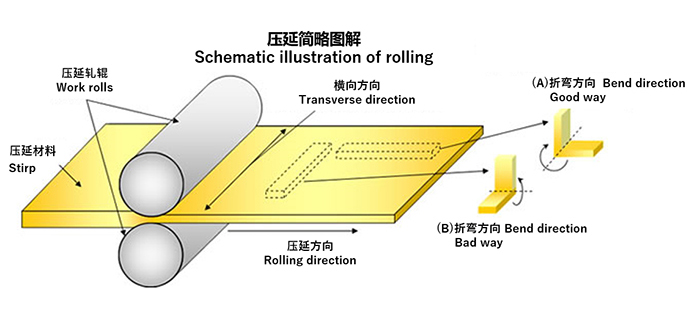

铜合金的折弯加工性取决于材料的压延方向。折弯直线与压延方向正交时为Good Way,平行时为Bad Way。